Healthcare / Net zero

University Hospital Ghent – CO2-neutral in 2050

By Simon Ossieur, Milena Bruyninckx and Petra Demoor | 17 Sep 2022 | 0

Simon Ossieur, Milena Bruyninckx and Petra Demoor describe a masterplanning and design project to restructure Ghent University Hospital’s 40-hectare campus over the next two decades, aiming for carbon neutrality by 2050.

Authors of scientific paper:

Abstract

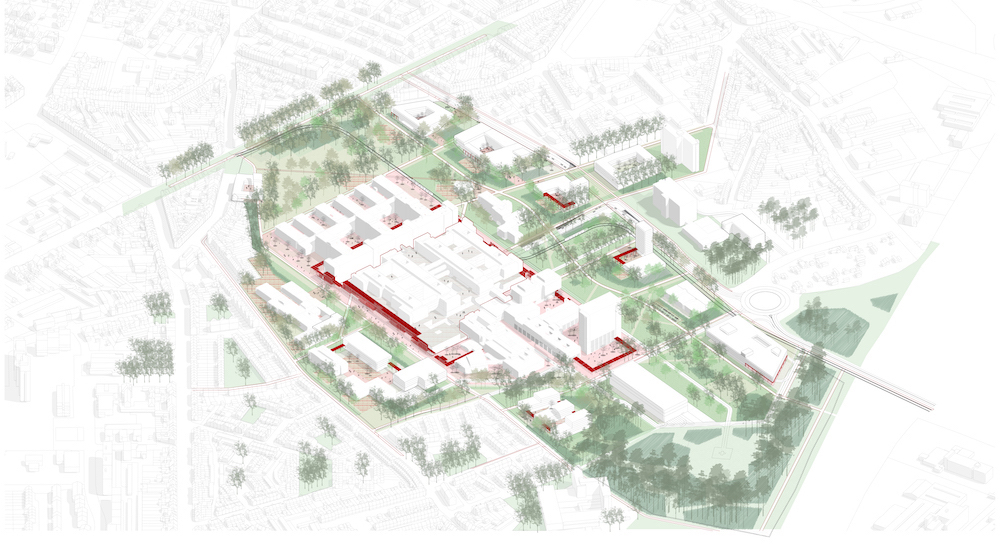

Ghent University Hospital is reorganising its 40-hectare campus over the next two decades and is aiming for a carbon-neutral campus by 2050. Together with the necessity for net-zero operational carbon emissions, Ghent University Hospital is also conscious about the environmental impact of infrastructure projects. The campus masterplan considers embodied carbon emissions, rainwater management, and the architectural needs to create a healing environment. Sustainable mobility with a reduction of car usage by personnel from 65 per cent to 47 per cent is also an integral part of the masterplan.

The main challenge to achieve net-zero operational carbon emissions by 2050 is decarbonising the heating supply. Therefore, the masterplan contains a route map, considering different heating supply options for 2050 and the transition phases. The chosen path will depend on factors such as evolutions in energy prices and technology maturity. Thanks to their low-temperature regime, the heating systems can easily adapt to any renewable heating supply. Cooling production will be centralised in a cooling plant, maximising the potential for energy exchange between heating and cooling. Instantaneous energy exchange will be performed by heat pumps connecting heating and cooling. Based on building energy simulation, approximately 30 per cent of heating demand and 40 per cent of cooling demand will be covered by this exchange. Different thermal energy storage systems will be considered for enabling more energy exchange. And rain water and fire suppression reservoirs will play a key role as an energy storage reservoir.

Photovoltaics can play a role for on-site electricity generation but carbon-neutral energy contracts are vital in moving towards net-zero carbon electricity consumption. Considering embodied carbon emissions, a life-cycle assessment was carried out to verify which load-bearing structure has a lower environmental impact. After analysis, it was concluded that a concrete structure is a better choice compared with a steel structure. Another challenge is the long lifespan of hospitals and therefore the need for a high degree of flexibility in the building. This is solved by implementing simple yet important design solutions: implementing a generic design, flat concrete slab structure on a regular square column grid; combined technical shafts and vertical circulation; and grouping of technical rooms.

Besides all the technical challenges, the aim must also be to create a healing environment for patients, visitors and staff. A wide variety of aspects are integrated in the design work, such as: open and inviting environments; a central public atrium; accessible roof gardens; and a building envelope with attention to daylight admittance for all users.

Keywords

In 2017, Ghent University Hospital started the decision-making process for a complete renewal of its hospital site. Ambitious goals were set right from the start.

A key decision was taken for the hospital to remain at the current location and undergo a total reconversion on site. Already embodied in this decision is one of the key points of an environmentally conscious decision-making process: in redeveloping the current site, the hospital will retain all the advantages of the urban connections established over the past 50 to 60 years, while also preserving the investments in materials made in the current buildings.

Increasingly, we need to take into account these kinds of decision-making processes – that open space and the amount of building materials to be used for infrastructure are as important – maybe even more important – than conscious energy use.

The masterplan, as developed, recognises four main design principles: a healthy, green campus; design for all persons’ wellbeing; an accessible campus; and ready for the future.

A healthy, green campus

The current university hospital campus is typical of many university campus designs throughout Europe, in that it was developed over decades in an almost haphazard way, leading to a fragmented situation, confusing wayfinding, and a lack of clear open space. The Ghent University Hospital was developed as two separate hospitals in two large building phases, one around the Second World War, and a second in the 1970s and ’80s. Both these sites were then integrated with one another to form the current hospital.

The proposed masterplan aims to counter this development. All medical functions will be re-integrated into a new centralised hospital building. This re-integration will free up space on the campus, so that a green belt can be created around the hospital and space can be freed for new spin-off developments.

A design for all persons’ wellbeing

The new hospital building will aim to provide a much improved healing and working environment. One of the main challenges of large-scale hospital infrastructure is the provision of sufficient daylight quality combined with a compact building. Among the main design principles employed, every patient room needs to have direct access to daylight. This is an essential design choice by the hospital, as the positive impact of daylight, mobilisation and outside air for many types of patients are long proven. The second principle is that working spaces in the medical “plinth” of the building need to maximum access to daylight. An accessible roof garden will provide an alternate means of creating more accessible green space for visitors, patients and staff alike.

Separate roof gardens are provided, even for ICU patients.

An accessible campus

An accessible campus is a design requirement on many levels. Through the choice of redeveloping an existing hospital site, the Ghent University Hospital retains the many advantages of already having good connections with the city of Ghent and its public transport network. A tramway enters the site directly, right up to the main entrance of the hospital.

Nevertheless, the existing site also poses challenges, as Belgium is one of the most congested countries in Western Europe. So, together with the implementation of the masterplan, the hospital also recognises the need for being more ambitious on limiting car use for staff commuting to the hospital. Providing more comfortable facilities for bike commuting will support this ambition. An underground bike parking of more than 2000 bikes is provided, compared with only 1780 car parking spaces.

Ready for the future

‘Ready for the future’ has implications on several aspects. Indeed, when building new infrastructure, besides the impact of direct energy use, we also need to take into account the embedded environmental impact through the creation of new building materials. We focus on both these topics in more detail below.

A CO2-neutral university hospital campus: Net-zero operational carbon emissions

On energy use, the masterplan aims to achieve net-zero operational carbon emissions. By this we mean that all energy to heat, cool, light, ventilate and provide internal electricity is generated without producing any net-carbon emissions.

Taking into consideration the total energy use for a hospital of this scale (about 930 bed positions), which approaches the energy use of a small city, this is no mean feat. Besides the technical challenges, there is also the growing uncertainty on the energy market to be taken into account. The main challenge will be how the hospital will address the carbon emissions of its heating demand.

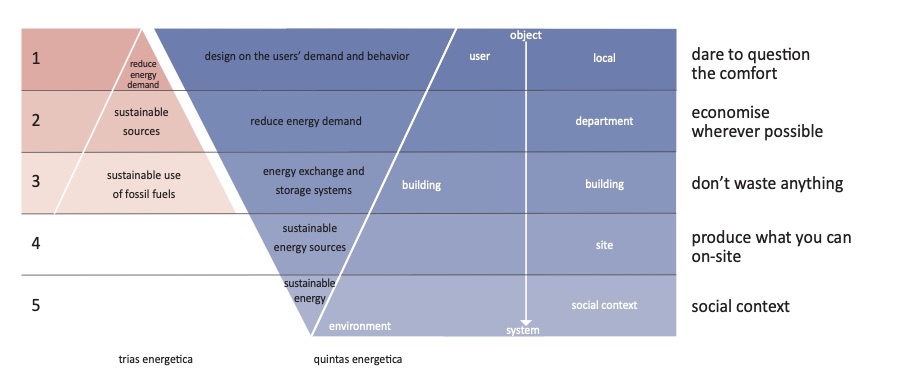

The methodology used to ascertain the way to achieve net-zero operational carbon emissions is an approach we call “quintas energetica”. This is a methodology based on the old idea of “trias energetica” but developed further with two additional principles.

When considering all design choices to be made, the path to achieving the goal can be summed up as follows:

- Design based on users’ requirements: It’s a given that the environmental conditions required in a hospital do not leave much room for compromise, as hygienic requirements require high ventilation rates, cooling loads for medical and data equipment, etc.

- Reduce energy demand: Measures can and will be taken to reduce energy demand where possible but, also, besides all the known measures to be taken, there is currently not much more room for fundamental improvement on the total energy demand.

- Energy exchange and storage: On this topic, there is much room for improvement in thinking about integrated design.

- Renewable energy sources: As technology stands now, electrification is currently the safest bet on the way forward to a CO2-neutral society. To achieve this will, however, pose significant challenges and the whole of society will need to contribute. Peak shaving and energy storage will play a key role in total electrification; just converting to electrical heating and cooling simply will not do if we’re to rely on renewable electricity sources. Renewable energy means we have to think in a more integrated way about energy flows.

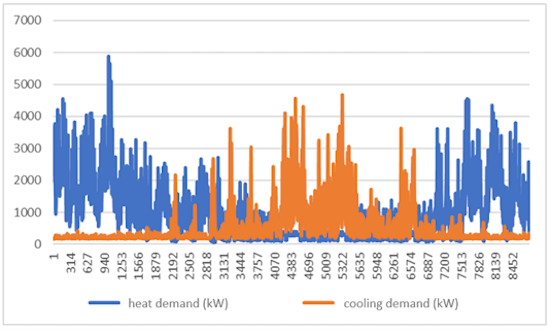

One of the more important issues that can be addressed by the fundamental choices of the temperature regimes for heating and cooling in the hospital is that of “wasted” energy use. When superposing the heat demand as well as the cooling demand for a typical hospital, we observe the two overlapping for at least 30 per cent of the time. This means that the cooling plant is literally blowing energy into the atmosphere as hot air.

One of the more important issues that can be addressed by the fundamental choices of the temperature regimes for heating and cooling in the hospital is that of “wasted” energy use. When superposing the heat demand as well as the cooling demand for a typical hospital, we observe the two overlapping for at least 30 per cent of the time. This means that the cooling plant is literally blowing energy into the atmosphere as hot air.

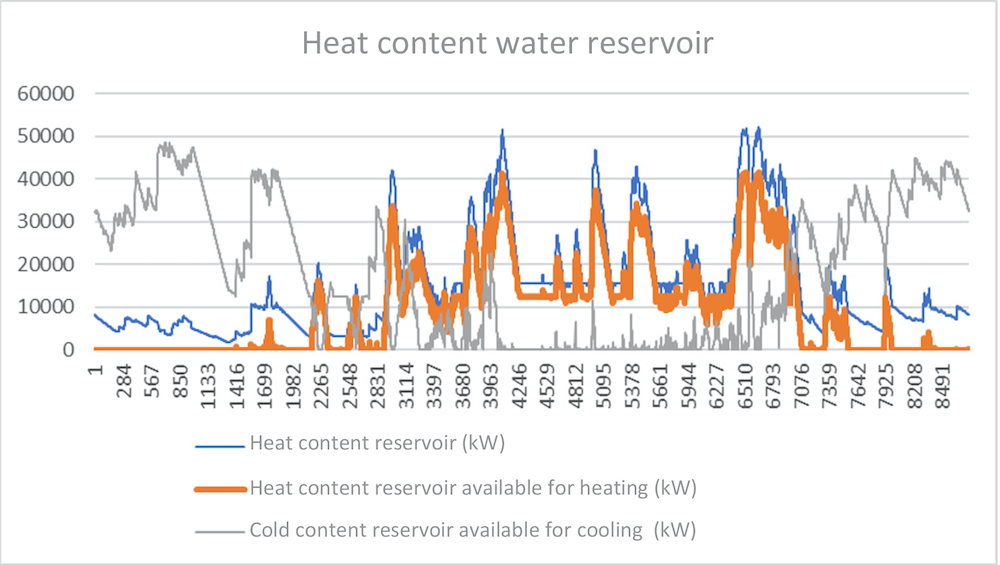

On top of this, when one takes into account the total amount of heating and cooling flow on a seasonal level, there is also a considerable amount of energy going to waste. In an ideal world, the total sum of heating and cooling flow should be a horizontal line – the difference between the total heating demand and the cooling demand. This would mean the entire difference between the two flows is either exchanged directly or transferred through seasonal storage.

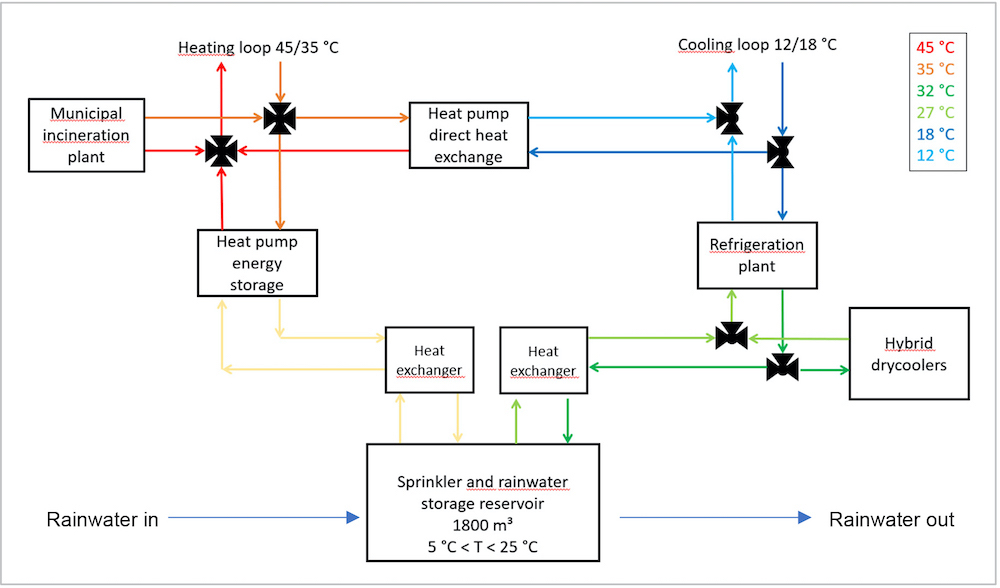

The hospital will aim to eliminate the amount of wasted energy through a clever integration of the infrastructure already in place. A double-acting heat pump installation will be implemented to exchange the difference in energy flow between the heating and cooling.

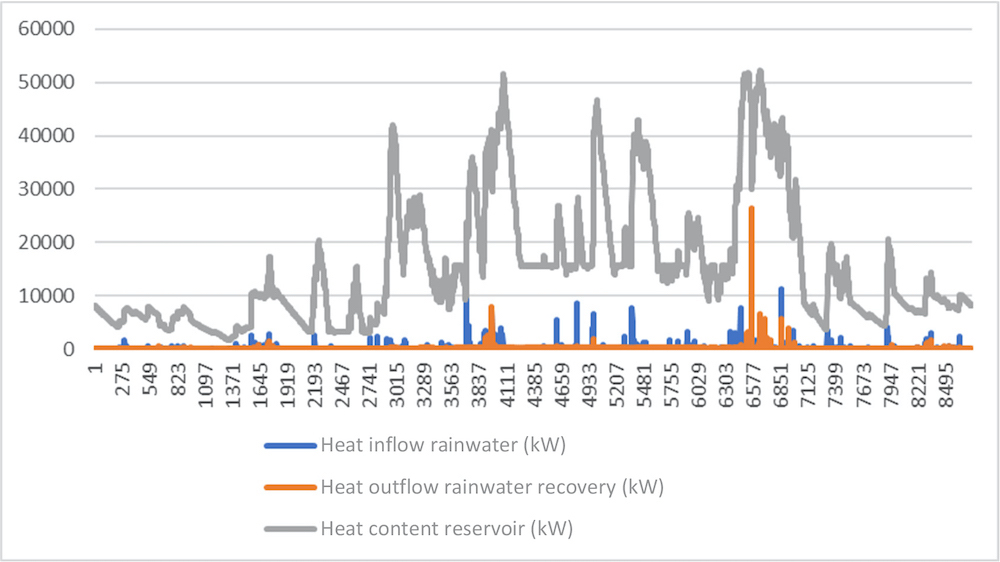

For seasonal storage, the sprinkler and rainwater reservoir will be used as a large “heat sink”, in which two heat exchangers will store the difference between heating and cooling on a seasonal (i.e. > 24h) basis.

The total heat demand for the new building infrastructure is estimated at 7800Mwh/year and the total cooling demand at 4600Mwh/year.

The heat pump for direct heat exchange will be capable of exchanging a total amount of heat flow of 2389Mwh/year and a total amount of cooling flow of 1991Mwh/year.

It could be argued that the most efficient design choice for seasonal storage would have been to use a borehole energy storage field. This design option was rejected because of unfavourable soil conditions, an insufficiently large free area on the site, and budgetary considerations. Through the implementation of direct heat exchange, the amount of energy to be stored on a seasonal basis is already reduced by quite a large amount. The option to use the sprinkler and rainwater reservoir as a two-way heat sink for cooling and heating is technically simple to execute, since the infrastructure is already present and makes it a very budget-friendly option. It does, however, pose some restrictions:

- firstly, the variation in water temperature will have to be limited to eliminate risk of freezing on the low end or creating too much bio-film in the water on the high end of the temperature range; and

- secondly, the energy in- and out-flow, through the in- and out-flow of the rainwater, has to be considered in the total energy storage capacity.

These two factors mean the amount of available storage capacity will vary through the year, as rainwater flows in and out of the reservoir.

The total energy flow was thus modelled together with the temperature restrictions imposed on the reservoir.

In total, we estimate the system will be able to extract about 328,000kWh of heat and around 617,000kWh of cooling from the reservoir on a yearly basis.

Altogether, this means we estimate that a total of 2717mWh/year of heating and 2608mWh/year of cooling can be exchanged for a total electricity flow of 85mWh/year of electricity needed for the heat pump, for energy storage and ancillaries in the heating and cooling loops needed for the energy storage.

How to reduce environmental impact of the building: Life-cycle assessment

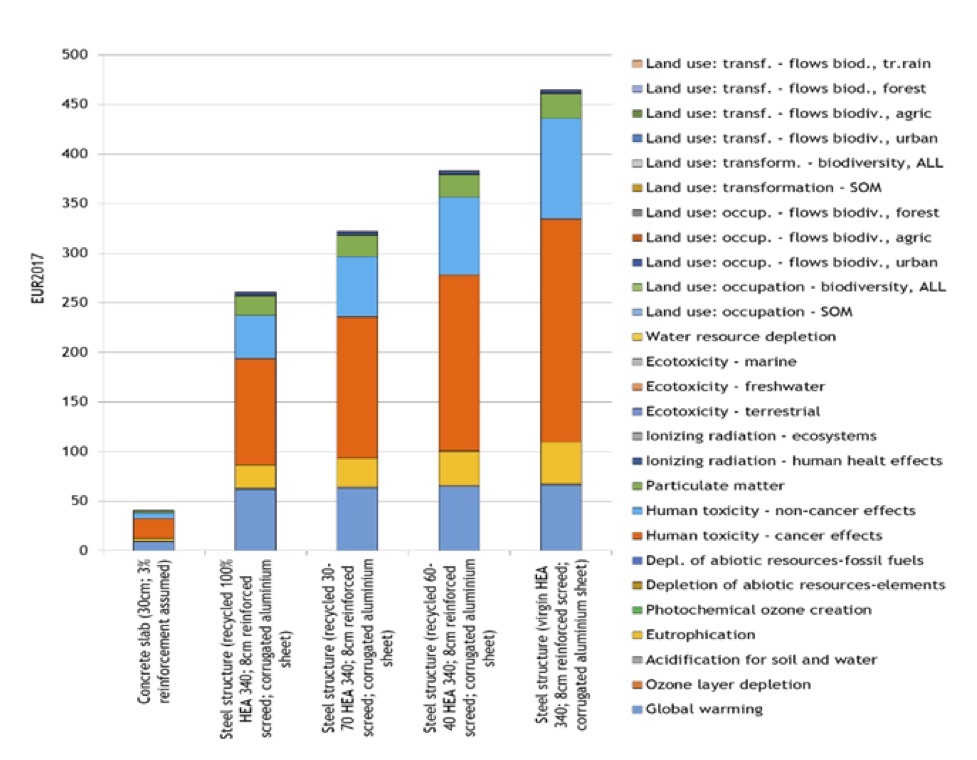

Besides the operational carbon emissions, we also need to consider the amount of “embodied” carbon emissions and environmental harm being done during construction. For this reason, life-cycle analysis was undertaken when making the design choices for the structure of the building. The most fundamental design choice is for the main structure of the building, for which different scenarios were evaluated against one another.

In essence, a concrete structure was compared with different design options for steel or steel/concrete hybrid structures. The main conclusion is that whatever is tried, a concrete structure has only one-tenth of the total environmental impact compared with any kind of steel structure. This has mainly to do with the inherently high energy use needed to convert iron ore into steel.

For this analysis, the life-cycle assessment (LCA) software SimaPro version 9.0, developed by PRé Consultants, has been used. For the life-cycle inventory of all the processes and materials, the Swiss database Ecoinvent version 3.4 was used.

Hypotheses

To compare the environmental performance of the concrete load-bearing structure against the steel one, four hypotheses were made for modelling the latter in SimaPro software. These four assumptions included the steel structure, comprising:

- virgin steel (100 per cent);

- combined virgin and recycled steel in ratio 60 per cent to 40 per cent, respectively;

- combined virgin and recycled steel in ratio 30 per cent to 70 per cent, respectively; and

- completely recycled steel (100 per cent).

Currently, only the production phase (A1) is considered in the analysis of the two structures. In this case, we modelled 1m² of the precast concrete slab (30cm thick) and compared it with 1m² of storey floor made of prefabricated steel (HEA 340 profile) with a screed (8cm thick with corrugated aluminium sheet).

Concrete structure

The precast concrete slab is assumed to be produced in Belgium. To produce 1m² of a 30cm-thick slab, we calculated that we would need 0.30m³ of concrete with a density of 2300kg/m³ (CEMII/B), and 3 per cent of reinforcement made of recycled steel (with a density of 7800 kg/m³).

Steel structure

In all hypotheses regarding the steel structure, we assumed that the HEA 340 profile would be used for the hospital load-bearing structure. To achieve the fire resistance stipulated in the Royal Decree of 6 November 1979 on protection against fire in hospitals, the steel is protected using the calcium-silicate boards.

Virgin steel

The first modelled structure made of steel is assumed to be produced using 100-per-cent virgin steel, i.e. low-alloyed steel. In Ecoinvent 3.4, this process produces primary steel, and scrap is only used for cooling the liquid steel. Included activities cover transports of hot metal and other input materials to the converter, the steel-making process, and casting.

Combined virgin and recycled steel, in ratio 60 per cent to 40 per cent

This structure is assumed to be made of 60 per cent of low-alloyed virgin steel and 40 per cent of recycled content. The latter includes metalworking manufacturing processes to produce a semi-manufactured into a final product. It includes average values for the processing by machines, the factory infrastructure, and operation. Furthermore, an additional steel input is considered for the loss during processing. Degreasing is not included and should be added if necessary.

Combined virgin and recycled steel, in ratio 30 per cent to 70 per cent

This structure is assumed to be made of 30 per cent of low-alloyed virgin steel and 70 per cent of recycled content. The latter includes the same manufacturing processes as described in the previous subsection.

Completely recycled steel

This is the highly optimistic assumption for the recycled steel structure and should be regarded as the best-case scenario if the market allows such rate of recyclable content. The process consists of metalworking manufacturing processes to make a semi-manufactured product into a final product, based on average values for the processing by machines, as well as the factory infrastructure and operation. Just as it is described in the above subsections, ‘Combined virgin and recycled steel in ratio 60 per cent to 40 per cent,’ and ‘Combined virgin and recycled steel in ratio 30 per cent to 70 per cent’, an additional steel input is considered for the loss during processing. Degreasing is not included and has to be added if necessary.

The method we used to compare the structures is MMG LCIA method 2017. This method is composed by the Flemish Institute for Technological Research (VITO), Belgium, commissioned by the Flemish Waste Agency (OVAM), Service public de Wallonie (SPW), and Brussels Environment (IBGE-BIM). It is the method used in the Belgian national LCA tool, called TOTEM (Tool to Optimise the Total Environmental impact of Materials), and therefore, the comparison is in line with the national assessment method. Besides the characterised scores per impact category, this method uses an aggregated single score indicator, expressed in monetary value (Euro). The aggregated score indicates the external environmental cost, or, in other words, the extent of the damage to the environment and/or humans, i.e. the cost to avoid, reduce or compensate the damage caused by environmental impacts to a given level considered to be sustainable1. The external costs are calculated by multiplying the characterised environmental impact with their specific monetary value; by adding these up, the overall environmental cost (single score) is obtained1.

This brought us to the conclusion that it is a far better choice to design a very flexible concrete structure to last over lifetimes than to opt for steel structures. Even if steel structures could theoretically be re-used through dismantling and 100-per-cent re-use of the structural elements, we would need to re-use them at least ten times.

So, if one considers a building structure to have a useful lifespan of 50 years, it would take more than 500 years before the steel structure outperformed the concrete structure on environmental impact.

About the authors

Simon Ossieur is project director at VK architects+engineers. Milena Bruyninckx is project engineer at VK architects+engineers.

Petra Demoor is a project manager at UZ Ghent, Belgium.

References

- Allacker, K, Debacker, W, Delem, L, et al. (2013). Environmental profile of building elements (MMG report). Towards an integrated environmental assessment of the use of materials in buildings. OVAM, Mechelen.

Organisations involved